East Coast Part Supplier and Warehouse Association Moderated Interchange Newsgroup > North Carolina

> Iron melting cupola furnaces melt cast iron

Iron melting cupola furnaces melt cast iron

bounce, yer money order will get lost in the mail and yer dog won't come home.

click on our "Contact Us" icon above for the quickest response to your questions.

IRON MELTING CUPOLA FURNACES MELT CAST IRON

IRON MELTING CUPOLA FURNACES MELT CAST IRON

IRON MELTING CUPOLA FURNACES MELT CAST IRON

IRON MELTING CUPOLA FURNACES MELT CAST IRON

IRON MELTING CUPOLA FURNACES MELT CAST IRON

IRON MELTING CUPOLA FURNACES MELT CAST IRON

IRON MELTING CUPOLA FURNACES MELT CAST IRON

IRON MELTING CUPOLA FURNACES MELT CAST IRON

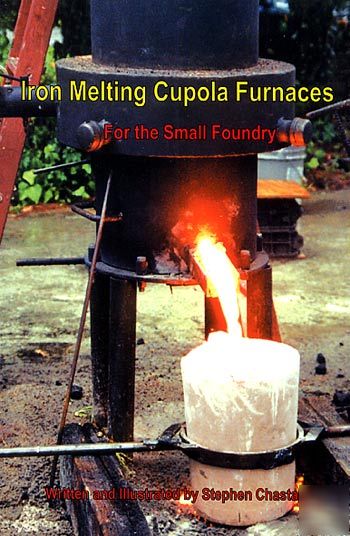

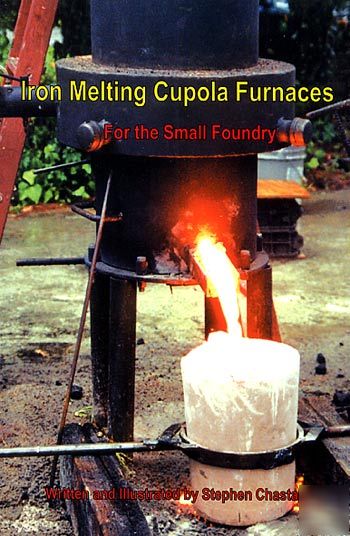

Want to make your own iron castings? In your own backyard? Steve Chastain did and now he'll show you how you can too!

"Old engines fascinate me. I love to restore old machines. Many engines and machines are scrapped because of broken castings. Parts are expensive or nonexistent. I had several machines that could be fixed if I could find a way to cast the parts.

"My first project was a set of pistons for an antique 4-cyl, generator set. After that I made manifolds, water-pumps, magnetos, and cylinder sleeves. When my friends found out I could pour iron, they started bringing me their projects. Along the way I learned that pouring iron is not as difficult as most people think."

Great book. Simply a great book because it really delivers! I watched a video of Steve's Iron Melting Cupola in action, WOW! It was something to see! Flames shooting skyward... Blinding streams of molten iron flowing into the ladle... Sand castings being poured... Makes me want to stop selling books and start pouring iron!

You get complete plans and operating instructions for a 10" diameter cupola. HOLD IT! Now before you thumb your nose at me and start telling me that 10" ain't much of a furnace, I must remind you that a cupola is a fast melting furnace and is measured by the inside diameter of the melting chamber. With nothing more than a shop vac you can melt 330 pounds of iron in an hour's time. Put on a high pressure blower and you'll get more than 600 pounds of iron an hour! You got a mold that big?!!.

And because you must have your sand molds already formed and in place before you start the heat, that means you'll need about 2 tons of molding sand to accommodate such a large amount of metal!

Steve will show you how to scale this fine little furnace up to produce more than a ton of iron per hour. But will you have enough sand for molds? I doubt it. You would need an army of gorillas to wheel that kind of melt...

Chapters include theory and design considerations, building a 10-inch cupola, cupola operation, air supply and blowers. designing centrifugal fans, construction of centrifugal fans, construction of pitot tube and manometer, calculation of air flow, additional cupolas based on the 15" shell, oxygen enrichment, purchase of coke and more.

You get a small book. It's so good you'll wish it were 500 pages. But readen taint the same as doin. Read the 128 pages, then get off your butt and build a furnace. The most difficult part will probably be getting the coke. And he'll advise you on that, too.

Fantastic book for the foundryman. This is solid red meat for the casting tyro! No fluff. Solid, proven how-to. It doesn't need to be any bigger - it's all here!

Soft cover 5 1/2" X 8 1/2" 128 pages, very well illustrated!

Visit my MarketplaceAdvisor Gallery! Power Tools for Power Sellers!

Phone: (***) 744-4449 M-F 9:00 to 4:00 Pacific Standard Time

This item has been seen by alt people!