East Coast Part Supplier and Warehouse Association Moderated Interchange Newsgroup > DC

> Services

> Replacement Parts

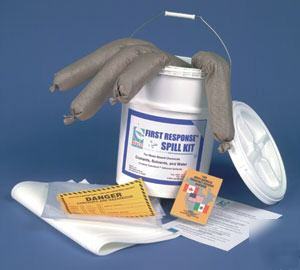

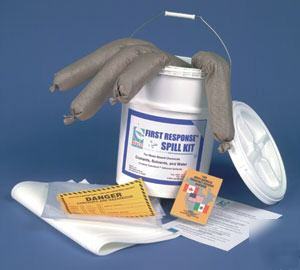

> 5 gallon spill response kit - spill cleanup

5 gallon spill response kit - spill cleanup

* Not all items are available at each location. Call and check on availability.

* Absorbs more than 5 gallons

* Re-sealable UN-Approved twist-top pail for easy access

* Easy to carry, easy to store

UniSorbTM Treated Polypropylene

UniSorb PlusTM Treated Polypropylene

30" x 48" x .004" Disposal Bag

wE ALSO OFFER A COMPLETE LINE OF PARTS FOR YOUR TANKS.

Chesser Container is a privately owned company that was founded in 1990. Our philosophy from day one has been...

“Providing the best quality service and highest quality products available to our clients.â€

With over 25 years of knowledge in the chemical industry, our perspective lends itself to both product knowledge and CFR compliance. Packaging compatibility is always at the forefront of our discussion with new clients and allows us to review all the options that are available. We bring our clients a wide selection of polyethylene, stainless steel and carbon steel tanks and intermediate bulk containers (IBC’s), as well as the necessary parts to complete the most important job, YOURS.

We offer a complete line of new and refurbished products.

Some of our valued clients include:

Take time to visit our website as well

tony.****@chessercontainer.com

Cleaning Procedures for Refurbished Units

Due to hazards of certain regulated materials, it is Chesser Container's strict policy that no IBC’s entering our facility will be recertified without first being thoroughly cleaned inside and out. Each IBC will be inspected once entering our facility and an assessment will be made of each to determine what parts and labor issues will be needed. This process is used for production scheduling and parts determination.

Chesser Container's recertification process begins with a complete cleaning of the inside and outside of the IBC. All exterior labels are removed as part of the cleaning process. This cleaning process consists of any or all of the following: cold water, hot water, steam, and chemical cleaning agents. The valve and lid are removed prior to cleaning and are cleaned separately by hand and/or machinery. If the valve and lid are serviceable after the cleaning process, the valve and lid will then be replaced. The IBC is again inspected and completely dried of all condensation. The IBC is then tested in accordance with CFR 49 Section 180.352 – Requirements for retest and inspection of IBC’s. Word for word documentation on CFR 49 Section 180-352 is available upon request.

Of course you are more than welcome to pick it up at one of our locations yourself.

click on our logo to see more products