East Coast Part Supplier and Warehouse Association Moderated Interchange Newsgroup > Pensylvania

> Production

> Welding and Gluing

> Pneumatic air press fixture w/ desoutter torque driver

Pneumatic air press fixture w/ desoutter torque driver

Torque driver is functional and spins when depressed. Torque driver controller is a Desoutter ESP 6 electronic screwdriver controller. Powers on and the torque driver spins but I did not test or change any of the settings as I did not have a manual or part to verify this with.

This machine is designed for pressing 2 parts together in a fixture. These fixtures are easily made and measure 5â€x5†and were made from HDPE or Nylon. Any material could be used including fiberglass. Two locator pins on the bottom allow perfect fixture alignment every time and 2 locking pins on the side hold it down. I will include one such fixture with the machine to see how they are set up. It is very simple to change out fixtures. A person could likely change out a fixture in 20-30 seconds with ease. Perhaps less. This machine is ideal for any production use where applications will vary and a consistent result is needed.

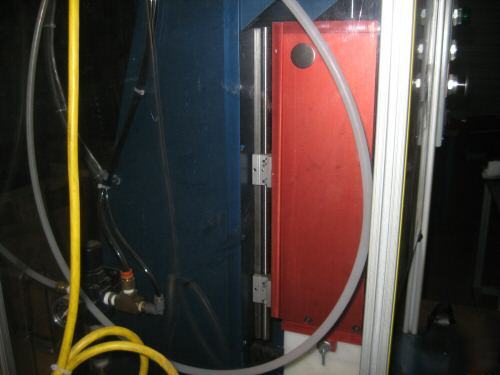

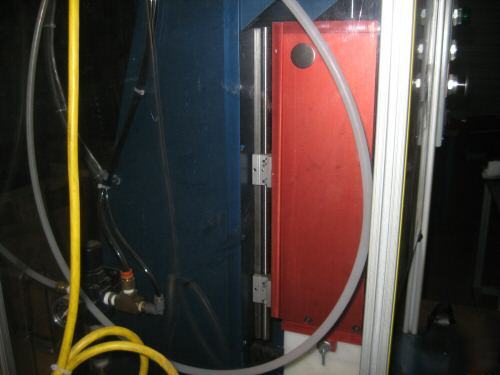

Unit is designed to press two parts together then on a linear slide (I think it is SMC but couldn’t see to verify) the torque driver is supposed to slide down and screw the parts together. Please note I was unable to get this slide to go down properly. All position indicators light up as they are designed and fuses are good. Perhaps this is due to a bad solenoid. I don’t know. In short, the I could not get it to actuate down although hen the air pressure was removed it physcially will go down fine. would need a some fine tuning.

Main housing for the torque driver is kept inline with a set of linear rails. This machine is solid!

Finger guards/locks/actuator’s are in place to actuate the press. Works well as I powered this up and tried it. This unit will require 2 hands as both require a finger in them to depress the unit. If a finger is removed before the press is all the way down, it retracts immediately. Place fingers back in the actuators to lift the cylinder.

E-stop switch functions and shuts machine right off. When powering up for the first time, a reset button must be pushed. Green light is functional but needs a new bulb. I verified this using a bulb from another machine but I had to put the bulb back so the working bulb is not included. Appears to be a basic bulb and nothing special but I don’t have an extra on hand.

Main unit is machined from aluminum. Uprights are milled from ¾†thick plate so there is a lot of rigidity to the press. Base is ½†aluminum. Table is mounted on 4 castors for ease of movement.

Unit came from a very clean environment for a large company. It is a bit dusty now from storage at my location. Guaranteed to be as described.

Table measures 36"x36" and is made from solid laminated wood.

Questions? Just ask and I will help as best as I can. Thanks for looking!~